Bridging the Gap in

Sustainable Packaging

Bridging the Gap in

Sustainable Packaging

Bridging the Gap in

Sustainable Packaging

Redefining Possibilities in Every Molecule

Looking Beyond Sustainability

Looking beyond Sustainability

Explore Tomorrow's Advanced Materials

The Grinloop® Odyssey

Hurdles in Plastics Ecosystem.

Plastics remain an irreplaceable material across countless industries, but their widespread use and growing scrutiny present unique challenges for members of the plastics value chain.

Machinery Constraints

Staying competitive requires substantial capital investments in advanced machinery and technology

Regulatory Compliance

Adapting to ever-changing regulations on plastic use, recycling, and carbon footprint remains a critical challenge.

Consumer Pressure

There is mounting demand to minimize the use of virgin plastics, driven by growing consumer awareness and environmental concerns.

Cost Challenges

Volatility in material prices, energy costs, and labor expenses poses a constant threat to profit margins.

Material Limitations

Materials that comply with new regulations often struggle to meet the performance demands of innovative designs

Hurdles in Plastics Ecosystem.

Plastics remain an irreplaceable material across countless industries, but their widespread use and growing scrutiny present unique challenges for members of the plastics value chain.

Machinery Constraints

Staying competitive requires substantial capital investments in advanced machinery and technology

Regulatory Compliance

Adapting to ever-changing regulations on plastic use, recycling, and carbon footprint remains a critical challenge.

Consumer Pressure

There is mounting demand to minimize the use of virgin plastics, driven by growing consumer awareness and environmental concerns.

Cost Challenges

Volatility in material prices, energy costs, and labor expenses poses a constant threat to profit margins.

Material Limitations

Materials that comply with new regulations often struggle to meet the performance demands of innovative designs

Embark on a Journey with GrinLoop®

We're not just presenting a material; we're inviting you on a journey.

Can your product evolve without a revolution?

With GrinLoop®, it's not just a question; it's a revelation.

Bridging the Gap in Sustainable Packaging

We're not just presenting a material; we're inviting you on a journey. Can your product evolve without a revolution?

With GrinLoop®, it's not just a question; it's a revelation.

Grinloop®*, is an ideal resin choice to address ever growing challenges of Packaging where conventional solutions stops. Creating sustainable high performance products with wide range of barrier properties in almost all types of machinery; it will be seamlessly integrated in your existing lines.

Its remarkable performance remains consistent in a wide spectrum of environmental conditions, making it a versatile and excellent option for various applications.

GrinLoop incorporated packaging is fully recyclable within PE recycling stream according to the most strict recycling crtieria in North America.

Ready-to-Recycle

GrinLoop provides excellent weather-resistant barrier properties covering a spectrum of barrier properties between High to Medium barrier applications.

Oxygen & Chemical Barrier

GrinLoop has obtained approvals from both the FDA (Food and Drug Administration) and Health Canada, allowing it to be used as a core layer in food packaging materials. These regulatory approvals signify that GrinLoop meets the necessary safety and quality standards for indirect food contact applications, ensuring it can be confidently incorporated into food packaging solutions.

Safe for food Applications

(LONO letter issued)

* Patented (Patent Pending)

GrinLoop provides excellent weather-resistant barrier properties covering a wide spectrum of barrier properties between High to Medium barrier applications. This covers Gas and Chemical barrier properties.

Oxygen, Methane, Radon, Chemical Liquids

GrinLoop incorporated packaging is engineered for the most efficient and abundant recycling stream. Fully recyclable within PE recycling stream according to the most strict recycling criteria in North America/EU.

Ready-to-Recycle

GrinLoop has obtained approvals from both the FDA (Food and Drug Administration) and Health Canada, allowing it to be used as a core layer in food packaging materials (indirect food contact). These regulatory approvals signify that GrinLoop meets the necessary safety and quality standards for indirect food contact applications, ensuring it can be confidently incorporated into food packaging solutions.

Safe for food Applications

(FDA/HPFB Canada)

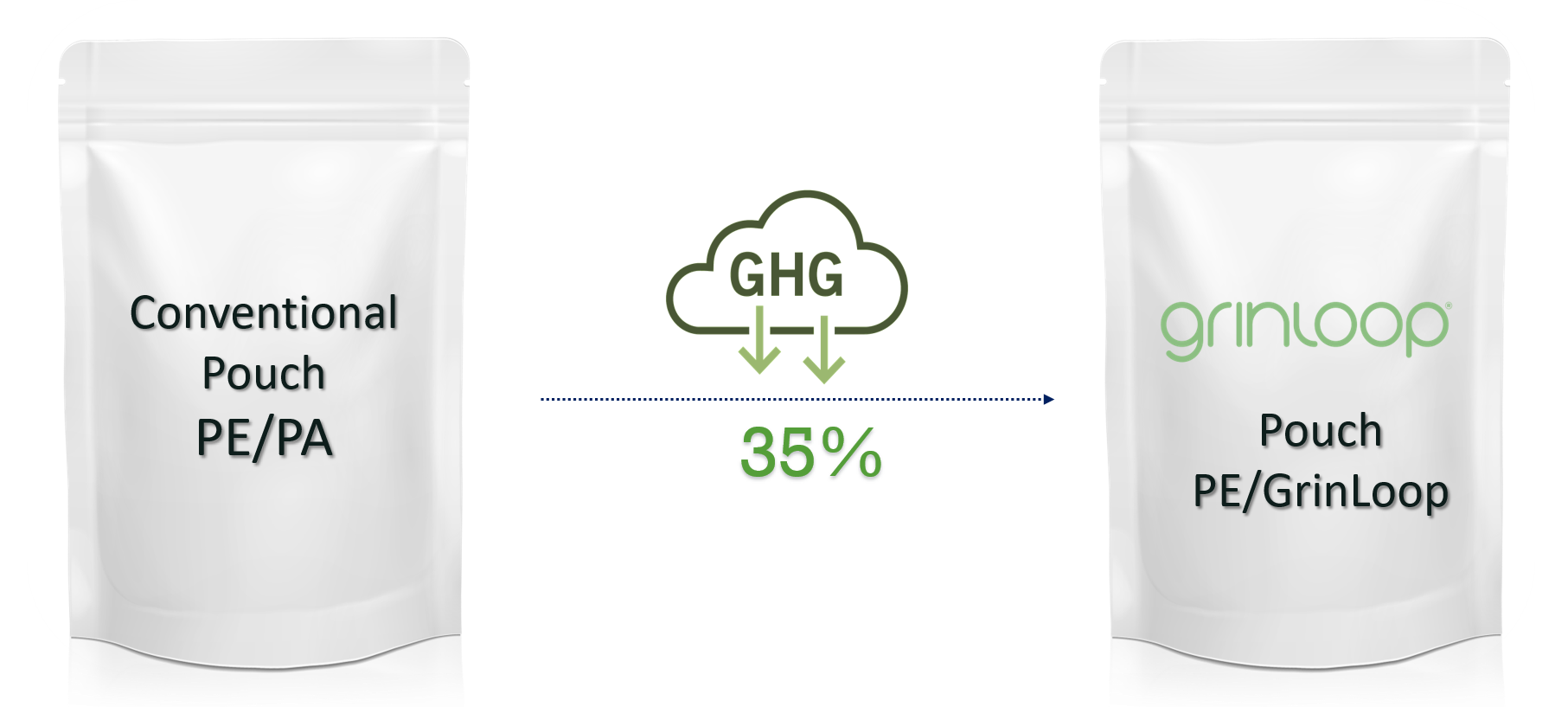

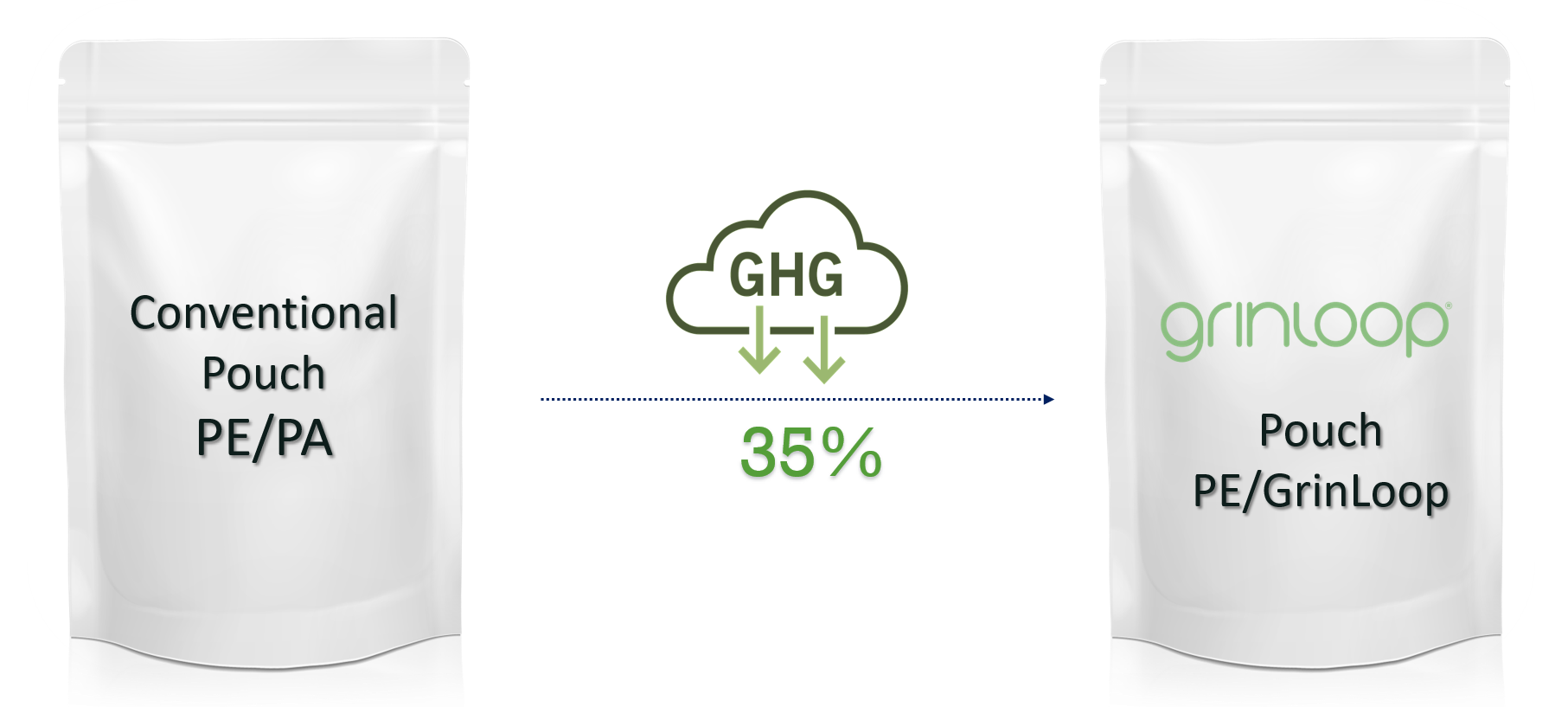

Incorporating GrinLoop® into your product structure can significantly lower the greenhouse gas (GHG) emissions of your products—by up to 35%, depending on the product structure, materials used and application requirements. This carbon footprint economy can even be acchieved excluding recycling step in some applications. An example is shown below.

Embark on a Journey with GrinLoop®

Embark on a Journey!

We're not just presenting a material; we're inviting you on a journey. Can your product evolve without a revolution?

With GrinLoop®, it's not just a question; it's a revelation.

GrinLoop®* is an ideal resin choice to address ever growing challenges of Packaging where conventional solutions stops. Creating sustainable high performance products with wide range of barrier properties in almost all types of machinery; it will be seamlessly integrated in your existing lines.

* Patented (Patent Pending)

GrinLoop provides excellent weather-resistant barrier properties covering a wide spectrum of barrier properties between High to Medium barrier applications. This covers Gas and Chemical barrier properties.

Oxygen, Gas, Radon, Chemical Liquids

GrinLoop incorporated packaging is engineered for the most efficient and abundant recycling stream. Fully recyclable within PE recycling stream according to the most strict recycling criteria in North America/EU.

Ready-to-Recycle

GrinLoop has obtained approvals from both the FDA (Food and Drug Administration) and Health Canada, allowing it to be used as a core layer in food packaging materials (indirect food contact). These regulatory approvals signify that GrinLoop meets the necessary safety and quality standards for indirect food contact applications, ensuring it can be confidently incorporated into food packaging solutions.

Safe for food Applications

(FDA/HPFB Canada)

Incorporating GrinLoop® into your product structure can significantly lower the greenhouse gas (GHG) emissions of your products—by up to 35%, depending on the product structure, materials used and application requirements. This carbon footprint economy can even be acchieved excluding recycling step in some applications. An example is shown below.

Features of GrinLoop®

Improved Protection

In varying humidity conditions and over extended time periods, GrinLoop has shown to deliver more stable barrier performance , maintaining reliable protection.

Lower Water Absorption

GrinLoop provides superior moisture resistance in barrier resin class of polymers.

Upgrading Your Capabilities

Using your existing machinery (e.g. 3 layer or 5 layer lines), you can experience indepency and produce your own barrier films/substartes.

Surpass Downguaging Limits

Thanks to its exeptional flexibility, ductility and OTR stability, GrinLoop enables significant film thickness reduction while maintaining flexibility and performance.

Expanded Design Freedom

GrinLoop supports innovative designs with its high PE compatibility, allowing up to 30% inclusion in PE layers while retaining monomaterial status. Unlock new possibilities for efficient, recyclable packaging structures.

Features of GrinLoop®

Features of GrinLoop®

Features of GrinLoop®

Improved Protection

In varying humidity conditions and over extended time periods, GrinLoop has shown to deliver more stable barrier performance , maintaining reliable protection.

Lower Water Absorption

GrinLoop provides superior moisture resistance in barrier resin class of polymers.

Unlock High Value Markets

Using your existing machinery (e.g. 3 layer or 5 layer lines), you can experience indepency and produce your own barrier films/substartes.

Surpass Downguaging Limits

Thanks to its exeptional flexibility, ductility and OTR stability, GrinLoop enables significant film thickness reduction while maintaining flexibility and performance.

Expanded Design Freedom

GrinLoop supports innovative designs with its high PE compatibility, allowing up to 30% inclusion in PE layers while retaining monomaterial status. Unlock new possibilities for efficient, recyclable packaging structures.

Discover How Grinloop Delivers the Benefits You Desire

Features of GrinLoop®

1

Stable Barrier properties

Ensures consistent quality, even in varying humidity levels.

2

Enhanced Production Efficiency

(Reduced transition time, Less scrap.)

3

Significantly Improved WVTR

(compared with other barrier resins)

4

High Barrier Structures on all Types of Equipment

using any type of basic or advanced equipments

5

Seamless Integration

Seamlessly adaptable with your existing infrastructure

6

Versatile Design Options

surpassing traditional material limits, e.g., beyond <5% GDR.

7

Responsible Sourcing

by using local eco-concious supplier for North Americans

8

Redefined Sustainability

Experience a material that champions eco-consciousness without sacrificing quality.

How it all started...

A Nation-wide challenge was addressed!

The demand for multi-layered products with strong oxygen barrier properties is essential across numerous industries. However, the complexity of these structures has made them traditionally non-recyclable, posing significant environmental challenges.

Recognizing this issue, we embarked on a mission to develop a sustainable solution. Our journey took a pivotal turn when Environment and Climate Change Canada, in collaboration with Innovative Solutions Canada, initiated a challenge aimed at reducing the environmental impact of food packaging waste. GrinLoop, our innovative approach, was not only chosen as the preferred solution but also emerged as the nationwide winner, affirming our commitment to tackling this critical issue.

FAQ

Yes, one of its major advantages is its compatibility with existing equipment. While some adjustments to processing parameters may be needed for optimal performance, majority of times, no change is required in the existing lines. Our team will guide you through this during initial trials.

GrinLoop stands out from other barrier resins because it can be incorporated up to 30% in recyclable product structures. This is a unique advantage not seen with other resins. As a result, designers have greater flexibility and creativity in their product designs.

Grinloop is made in Canada currently and the expansions are planned for EU production in 2025.

And Yes, GrinLoop is now commercially available.

Absolutely! GrinLoop ships worldwide.

GrinLoop is likely one of the smoothest barrier resins you'll process. Before introducing GrinLoop, simply purge out any previous resins from the extruder. After your run, a quick purge with LDPE will quickly clean up your extruder.

No, GrinLoop is versatile and can be used for a range of barrier requirements (depending on the grade), from high to medium.

Knowledge Centre

GrinLoop® in Real SL Testing

In this short article we summarize the interesting characteristics of GrinLoop®'s (High Barrier Grade) OTR and WVTR and its efficacy in various food Shelf Life tests.

GrinLoop® in Challenging Barrier Applications

(e.g. Cheese Packaging)

This article discusses how GrinLoop® provides a unique sustainable solution for the applications where a certain medium barrier properties are required.